At Blue Ocean Development, we take great pride in our homes. We spend time on every detail of their construction, from design all the way through finished build, and as a result our homes look and, more importantly, feel cohesive. Have you ever thought about how many distinct systems go into a completed home? Of course, you need a roof and four walls, and a couple of doors. You need plumbing and electricity. Windows are nice, and insulation helps with heating costs. But these are only the obvious features. Once you really start to dig into the details, you’ll find an endless litany of tiny decisions, each one supporting and affecting the next, all of them essential to the finished product. Understanding these choices, and aiding you in making ones that create harmony in the finished work is our business - and we’re tremendously proud of it.

Our latest project at 1283 Serenity Woods Drive, showcases our attention to detail from its design and construction, to the exterior, interior, and finish work.

Design and Construction:

The first and most important step to creating a home that both looks and feels unified is to carry a single idea throughout the entire construction process. At Blue Ocean Development, we consider sustainability to be the principle rule of construction. We strive for efficiency and for ecological responsibility in everything we do. To carry out this vision, we employ key features, such as:

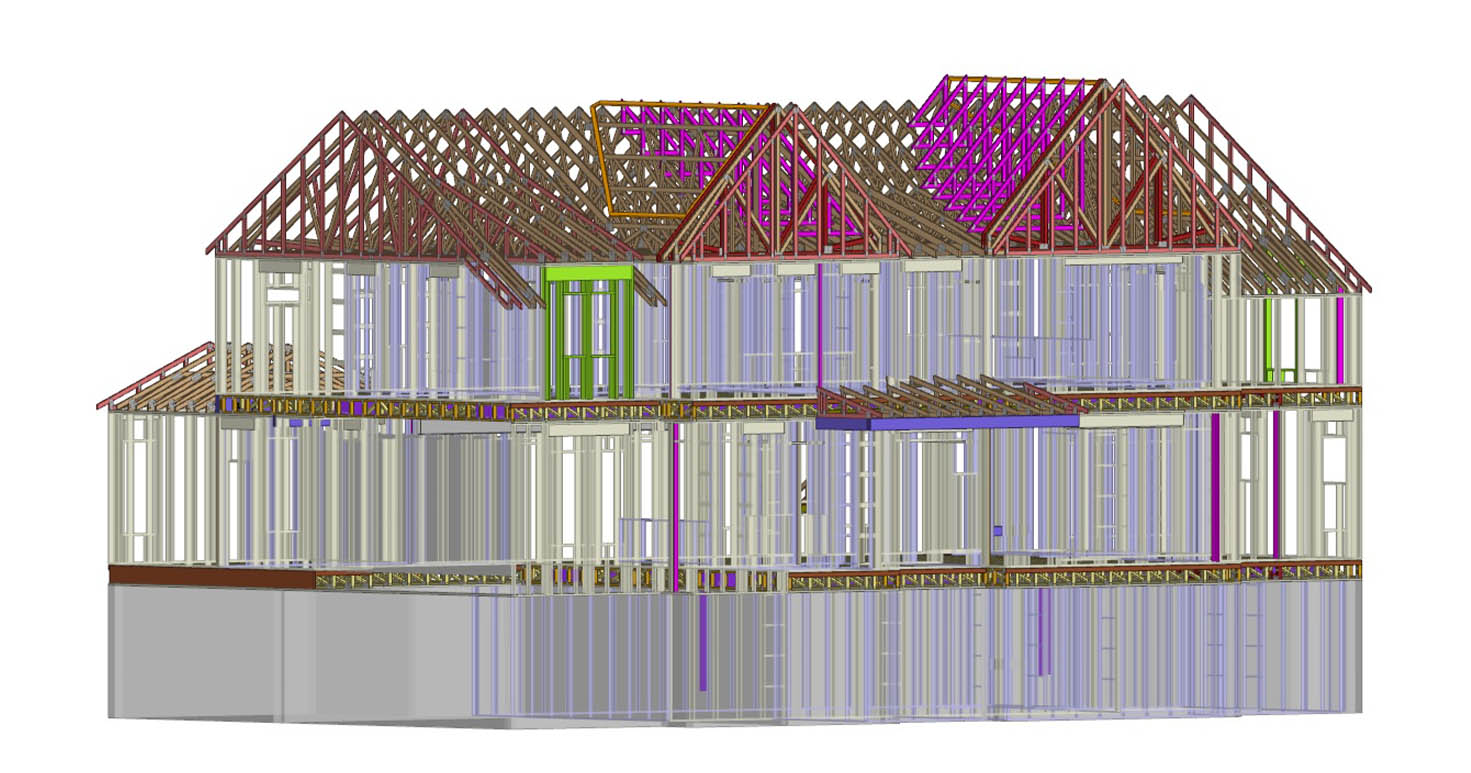

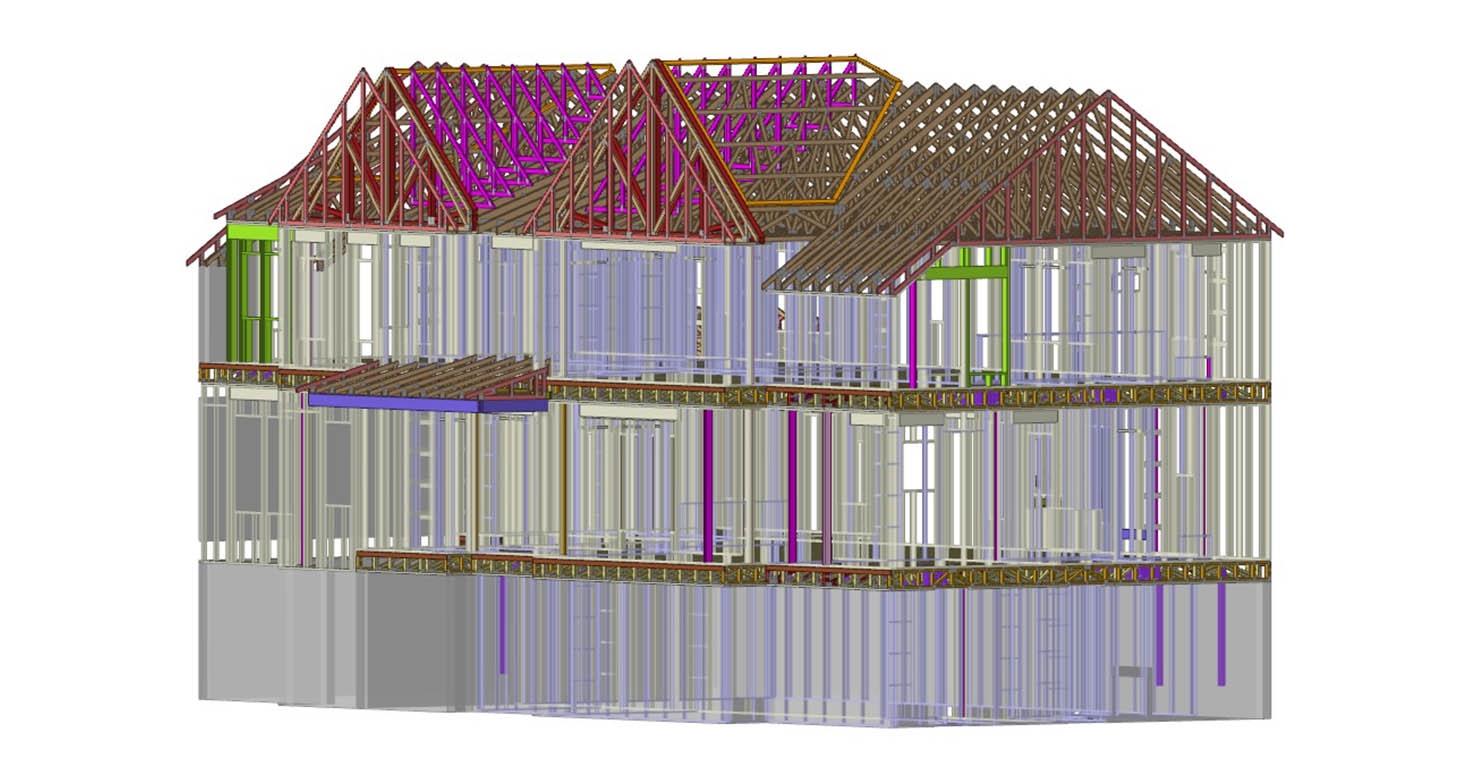

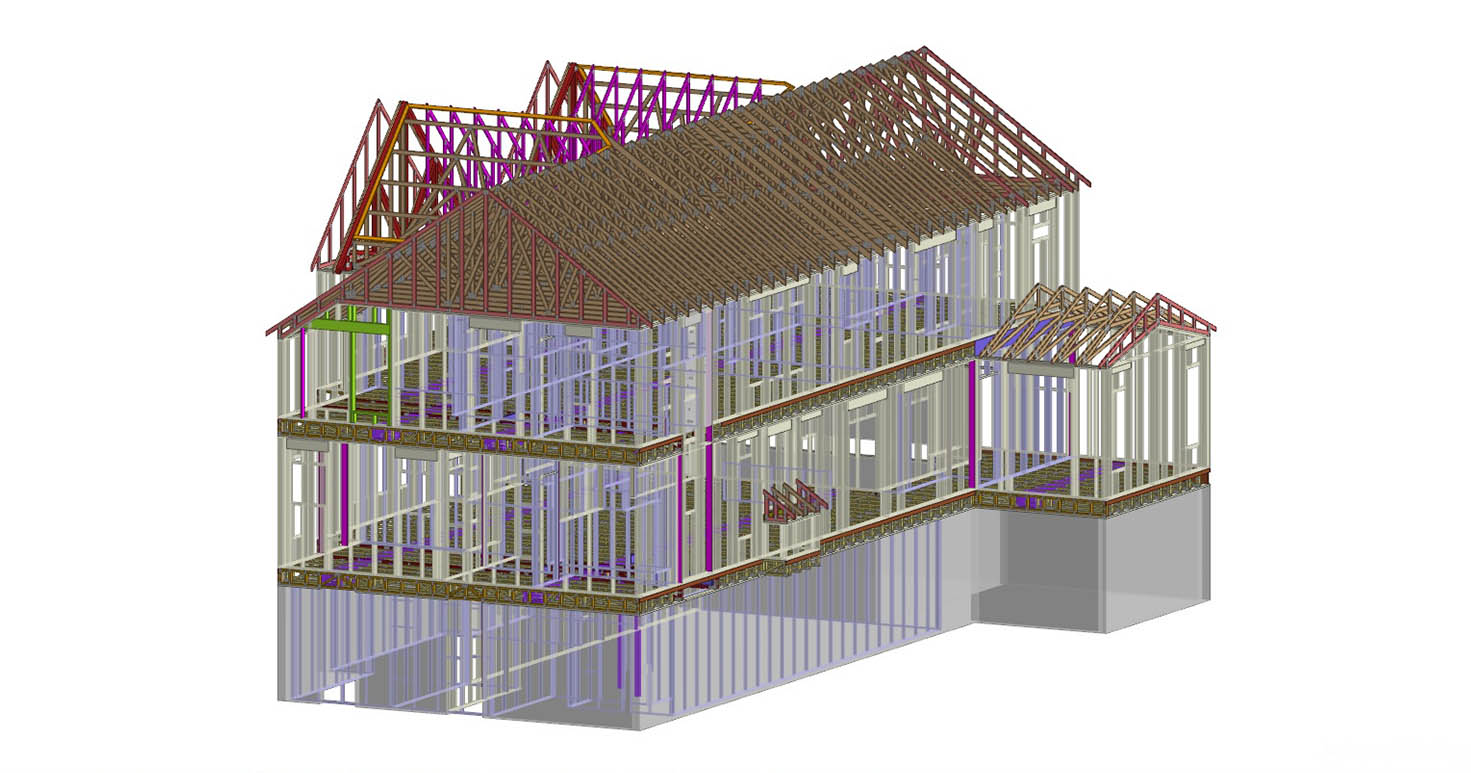

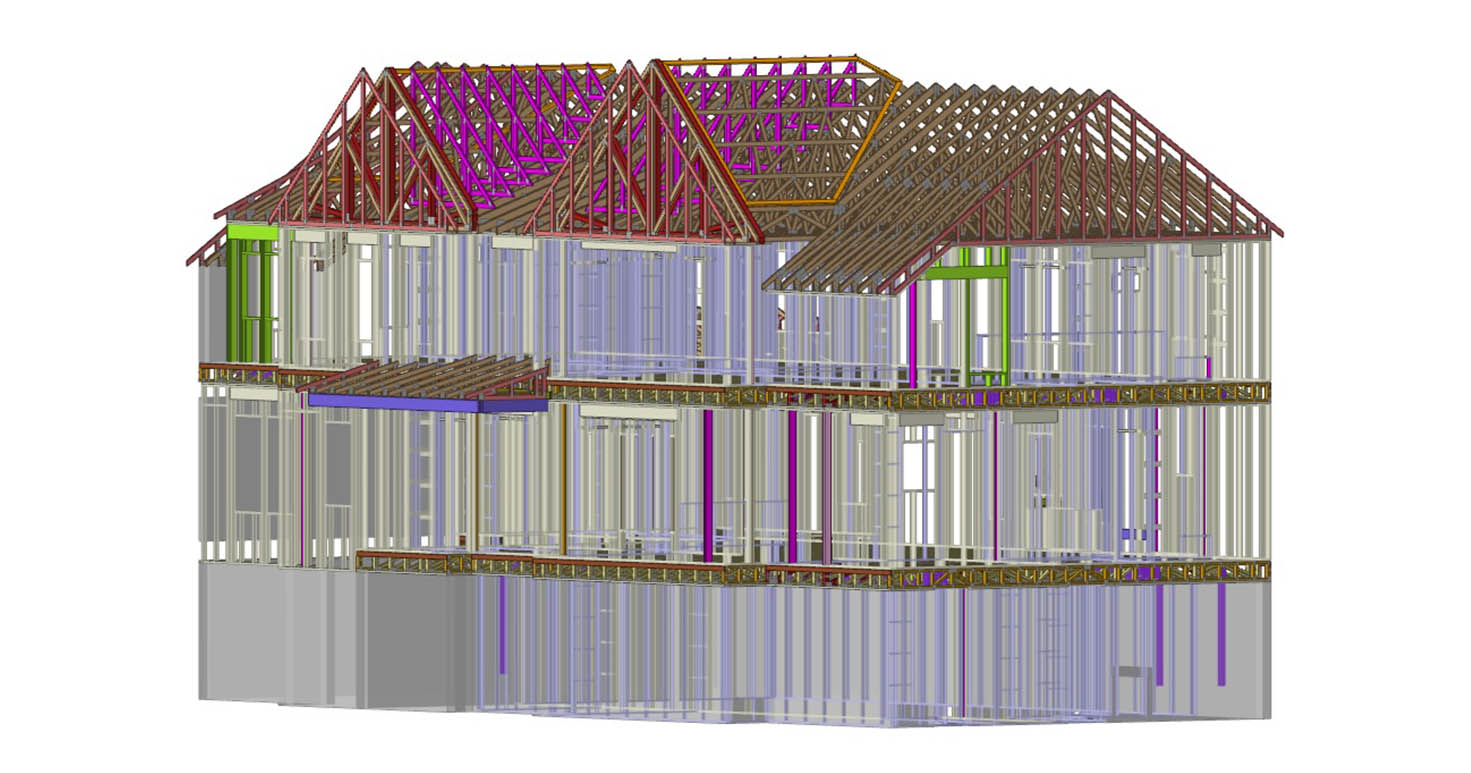

BIM Modeling - Firstly, we use a cutting edge 3D modeling software to design our homes. By laying out the project in a 3D environment, we are able to seamlessly integrate each separate system that goes into making the house, from structural building components to HVAC systems, electrical wiring, and plumbing. This removes the necessity of post-build modifications that could harm the structural integrity and the look and feel of the home, and makes our houses a single, unified organism.

Energy Star Certification - Secondly, we ensure that each of our homes receives an Energy Star Certification by choosing structural components that meet the highest standards of durability and energy efficiency. A great example of this is our use of Huber Zip-Wall R-3 Technology. Zip-wall tech provides pre-built panels that are insulated before installation rather than after. This streamlines external water, air, and thermal management and severely reduces energy loss. But our attention to details doesn’t stop there - after all, what use are airtight walls if the windows leak? That’s why we’ve chosen industry leading Andersen 100 Series windows. Made of Fibrex® composite material, these energy saving windows are 2x stronger than standard vinyl, and can withstand temperatures in excess of 150 degrees.

Why Use Panelized Building Systems?

- Significantly reduce the production time

- Reduce jobsite waste

- Reduce the lumber consumption

- Increase production quality

- Decrease time-to-completion